I want to make my first post an explanation of how I was introduced to the world of Koa wood. I’m very grateful for the opportunities I’ve had to be involved with Hawaiian forestry, but the journey has been a challenge that humbled me and taught me to never give up the pursuit of my dreams.

I graduated from college in Chicago and right after moved to Hawaii. I didn’t know a thing about Koa wood at this point. I lived with a friend from university and when our diplomas arrived, he talked about getting his framed in Koa. This was the first time I heard of the wood and while it did look nice, I really couldn’t afford the high price. I just didn’t understand the value of this special wood at this point in life.

I worked with my friend at his dad’s construction company for about a year and then went on to work with a high-end custom cabinet shop manufacturing cabinets. The job was very satisfying because I got to use my hands to work with wood daily, and wood working is something I’ve been passionate about since I was a child. I loved milling hardwoods and creating beautiful kitchens for people to enjoy. My second introduction to our island’s special wood came when we were hired to create an entire kitchen out of Koa.

The kitchen was gorgeous, and we made several more beautiful projects after that but soon after an economic recession caused us to be without work for several months. At that point I was forced into homelessness and did everything I could just to survive.

Without cabinet work and unwilling to work a desk job, I resorted to using the leftover Koa wood from our cabinet project to create a picture framing business I called Aloha Woodcraft. I sold frames on Amazon, Etsy, eBay and locally through Craigslist. The picture gave me just enough cash flow to survive the rough patch in my life and it also let me stay involved with Hawaiian woods. I also must mention that without the help of my wonderful wife (girlfriend at the time) I never could’ve made it through this rough period.

Eventually we ran out of falloff material for my Koa frames and I was forced to find a local wood supplier. I turned to Plywood Hawaii who originally sold us the lumber for the job, but they couldn’t get their hands on any because of the lack of supply. They recommended I check Winkler Woods and this introduction led me into the second phase of my experiences in Hawaii.

I was a customer of Winkler Woods for about a year before working there. I would hunt through the shop for hours looking for the perfect sticks for my picture frames. At the time the shop had piles of Koa wood from wall to wall, floor to ceiling. Finding Koa lumber took quite a while, but I didn’t mind because I was grateful to be working with such an amazing wood. One day when I went for more Koa, I was notified that the operations manager had quit suddenly and that it would be a while before I would be able to get more wood for my frames.

At this point I was burnt out from building cabinets and I was ready to move on to a job that let me pursue my passion and utilize my college degree. I asked the owner of Winkler Woods if he needed help at the shop. That led to a 3-year career that exposed me to the amazing world of Hawaiian woods.

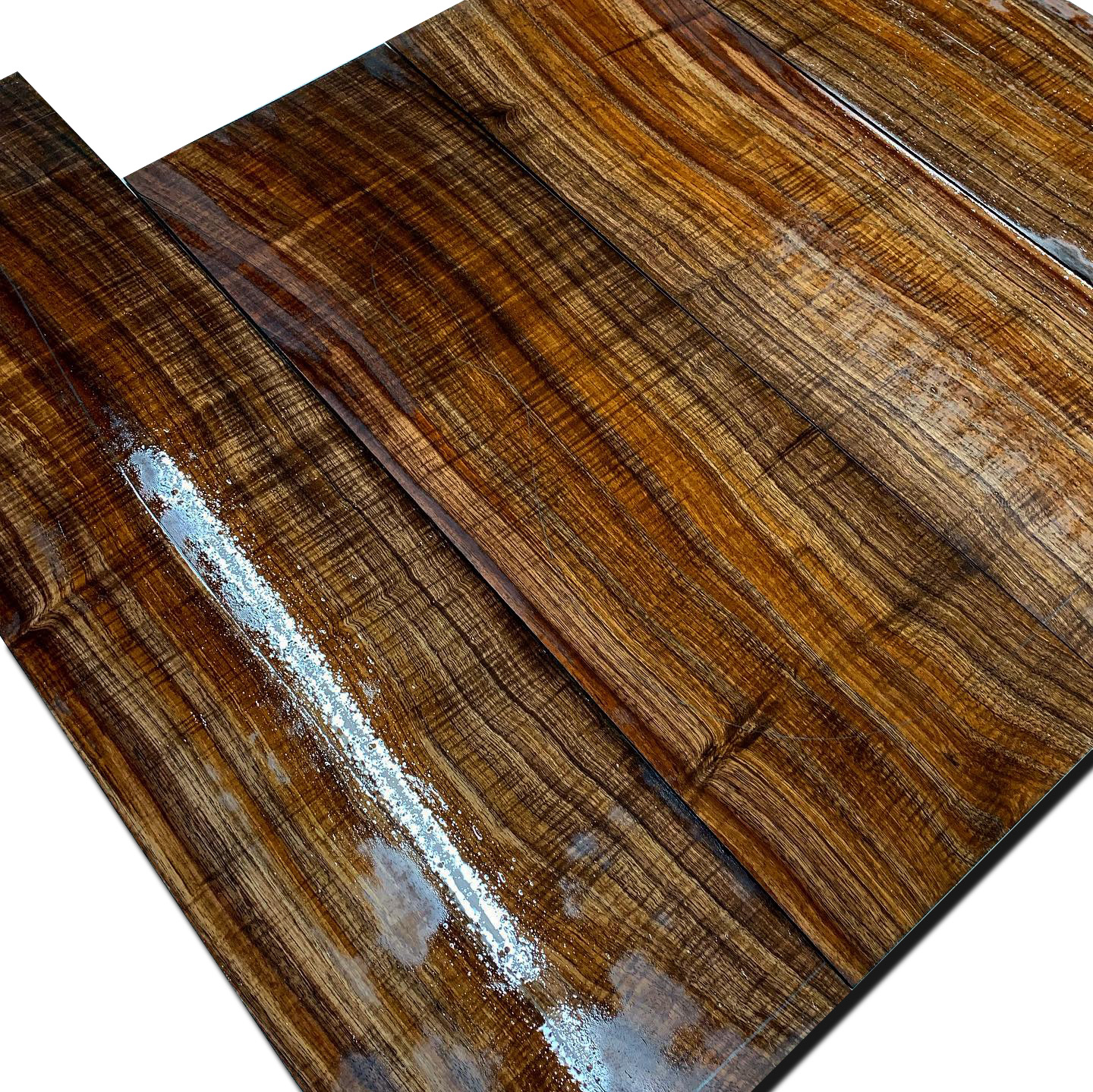

We manufactured all things Koa. We had an ukulele factory where we made handmade instruments from beginning to end. We manufactured raw building materials such as paper veneers for plywood, Koa moldings for picture frames, Koa T&G flooring, custom furniture and much more. The main product we produced was Koa instrument sets for ukuleles. In addition to ukulele sets, we sold Koa lumber and Koa guitar sets. I got to meet the most interesting loggers and landowners on Big Island in the rarest forests of the world. Most importantly, I got the chance to form amazing relationships with people in many different industries that utilize our island’s rare wood.

I loved the job but challenges in the shop forced me to leave the company. I did so with a heavy heart, but I had to move forward. In early 2018 I left Winkler Woods and started working with a construction company that builds custom homes on Oahu.

After about six months of serving the construction company as their business developer, I started to miss Koa. I felt the world of Hawaiian woods calling my name and I decided to make my first solo trip to Big Island to get more wood. I got a modest amount of Koa lumber and started the website Koality Woods to show the music manufacturers of the world what I could offer.

Today, I’m still serving the construction company as their business developer and the remainder of my time is spent working with Koa wood. I love working with Koa so much and I’m so grateful for the opportunity to be involved with Hawaiian woods. I hope you feel as passionate as I do about our very special wood!

I’ll continue this blog sharing insights into the little-known industry of Hawaiian forestry. There are many amazing woods that are unique to our islands. Even trees that are found elsewhere just seem to grow better in our forests. Follow along for many stories from the Hawaiian forests!